EcoVeyor Benefits

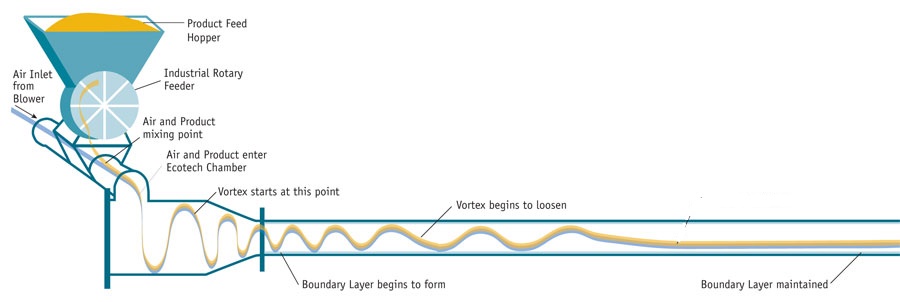

The Ecotech Process is the result of over 20 years and millions of dollars in research, development, and testing. Using the patented EcoVeyor™ flow processor, turbulent air is shaped by the proprietary mixing chamber into an organized airflow, reducing turbulence and cushioning the pipe resulting in minimal pressure loss, reduced product attrition, minimal pipe line wear, lower energy costs, and lower maintenance down-time.

The EcoVeyor™ is simple and cost-effective to install, operate, and maintain. Ecotech offers its customers, turnkey systems designed to meet their needs, retrofits of existing pneumatic conveying systems, or the EcoVeyor™ processor as a stand-alone product.

The patented Ecotech technology, the EcoVeyor™ flow processor, organizes and shapes the airflow to provide significant operational benefits:

Lower product attrition = increased value

Lower pipe wear = longer production life

Lower energy and less maintenance = lower cost and less downtime

Long-distance and high-angle conveying = lower transportation costs

Positive environmental benefits through closed-loop design = good stewardship

Separation of particulates by mass = increased product value

Non-thermal moisture removal = lower energy costs

Modular system design = low impact on space and lower start-up costs

The addition of the EcoVeyor™ to an existing low-pressure blower system will provide an immediate efficiency gain in the operation, with modest new capital investment. Once installed, the EcoVeyor™ will reduce costs by increasing longevity of system components through lower line and component wear as well as increased product yields through lower product attrition rates.

Note: SpiroFlo uses the trade names Ecotech Systems and EcoVeyor™ for solids conveying and non-thermal drying applications.